The LIFT manufacturing evaluation institute reported a model new development under its sponsorship involving a way for producing personalised powdered metallic alloys. The evaluation by undergraduate teams at Michigan Know-how Faculty reportedly will contribute to creating new provides and “freeway maps” for hypersonics features.

LIFT is a public-private partnership of the U.S. Dept. of Safety and a variety of business and academic pursuits, working to stipulate manufacturing processes for lightweight provides. Michigan Tech may also be working with LIFT inside the ongoing Hypersonics Thermal Administration and Supplies Acceleration purposes, funded by DoD, to stipulate roadmaps for creating alloys and processes for industrial, off-the-shelf provides that could possibly be produced by additive manufacturing for hypersonics.

Hypersonic weapon packages perform at speeds of Mach 5 or bigger nonetheless in low-Earth atmospheres. Rising such weapons, along with a house present chain for them, are amongst DoD’s prime priorities.

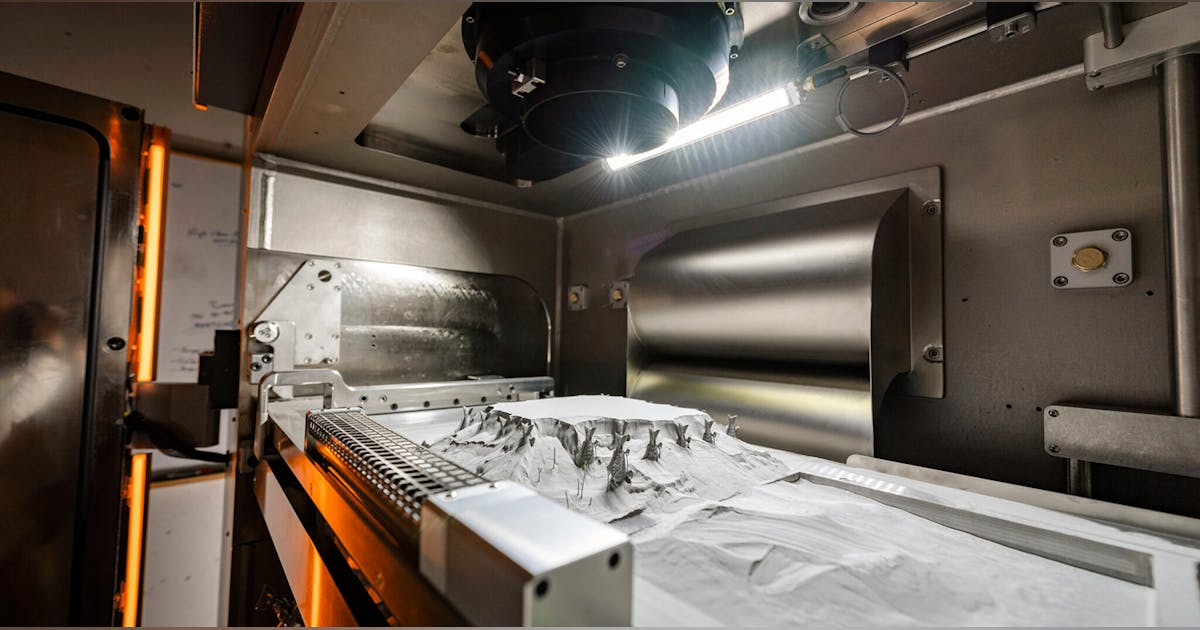

The model new powder-metal manufacturing course of was developed by 4 teams of Michigan Tech school college students and entails a 10-ft-tall modular chamber into which molten metallic is poured via a funnel, after which atomized using a high-pressure gasoline nozzle. The powdered metallic thereby created is collected from the underside of the chamber.

The chamber is designed to atomize about 88 lbs. (40 kg) of metallic, along with ferrous metals, nickel-based alloys, and aluminum-based alloys.

Atomization is a typical manufacturing course of for PM nonetheless the manufacturing functionality is proscribed for the sorts of alloys needed for superior evaluation purposes, and Paul Sanders, a Michigan Tech professor of Provides Science and Engineering who served as college advisor to the 4 teams, said the teams’ work will promote development of newest alloy metallic powders.

“This atomization performance is required because of current powders for metallic additive-development initiatives are expensive and have prolonged lead-times,” in response to Sanders. “This chamber, if constructed and deployed, will current for improved powder additive alloy design faster and at a lot much less worth all through commerce.”

LIFT’s chief know-how officer Noel Mack said at current on the market parts for custom-made PM alloys are each too small or too huge for environment friendly evaluation. “The potential for creating purchaser powders particularly portions might tempo up our innovation processes of future features, just like provides for hypersonics, and because of this truth tempo up the adoption by commerce,” Mack said.

Michigan Tech may also be partnered with LIFT inside the ongoing Hypersonics Thermal Administration and Supplies Acceleration purposes, every funded by the Dept. of Safety, to develop roadmaps for alloy and course of development for off-the-shelf provides for additively manufactured elements, for use in hypersonic features.