Otto Junker GmbH tales it has a contract to place in a model new coreless induction furnace operation for Hydrotec Utilized sciences AG, Wildeshausen, Germany. The family-run foundry produces manhole covers, drainage channels, flooring packing containers, and completely different cast merchandise for gardening and landscaping.

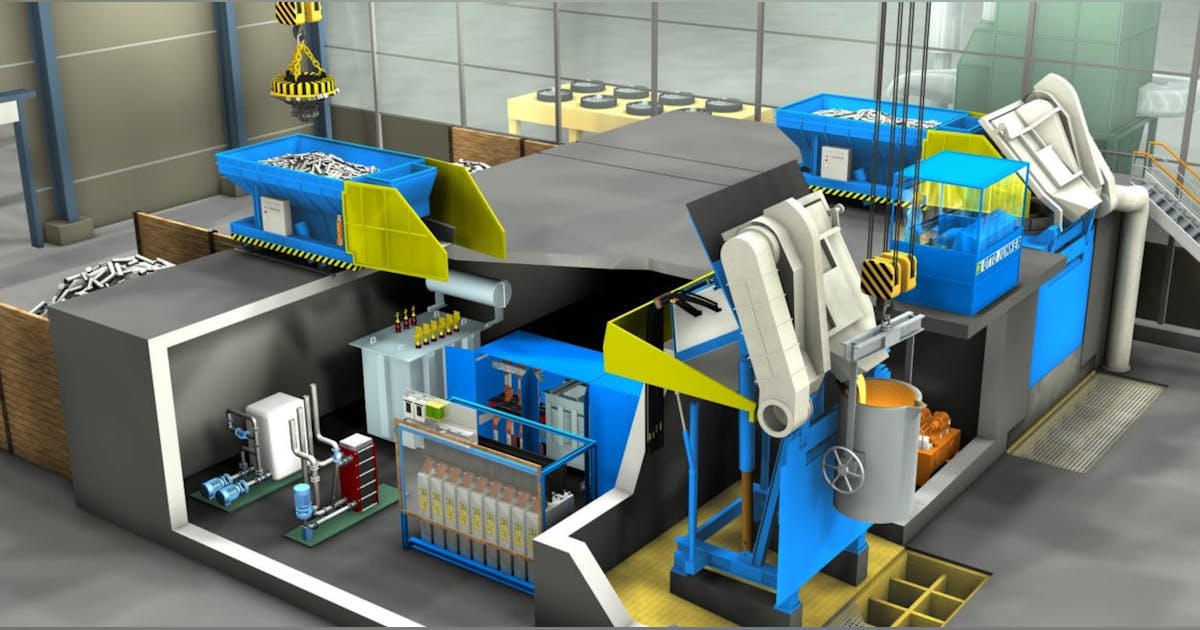

The purpose of establishing a model new iron foundry now in Europe is “to appreciate independence and suppleness,” and to contribute to native climate security, promote the native financial system, and create jobs. The order is for provide, arrange, and commissioning of a model new Otto Junker Duomelt JupiterLine coreless induction furnace plant, with two, five-ton coreless induction furnaces to be supplied with electrical energy by IGBT PowerCube know-how for vitality distribution.

As outlined by Otto Junker, its twin furnace methods with a shared IGBT frequency inverter makes use of optimizes electrical vitality consumption by delivering melting energy to at the very least one vessel whereas sustaining the metallic warmth throughout the alternate unit.

Its JupterLine furnaces have a functionality for 2 to eight metric tons of iron.

For the Hydrotec arrange, the model new instruments can have a communication interface to a giant photovoltaic (picture voltaic energy) system by a higher-level energy administration system. The glycol-free air/water recooler will seemingly be equipped with a heat restoration system which will present heat to part of an connected developing in a “sustainable and environmentally nice” methodology to an connected developing. Additional heat will seemingly be be offered to a district heating group.

Otto Junker well-known that the model new arrange’s Industrie 4.0 customary will seemingly be complemented by a patented OCP+ coil monitoring system, promoting sustainability, energy effectivity and native climate neutrality necessities.