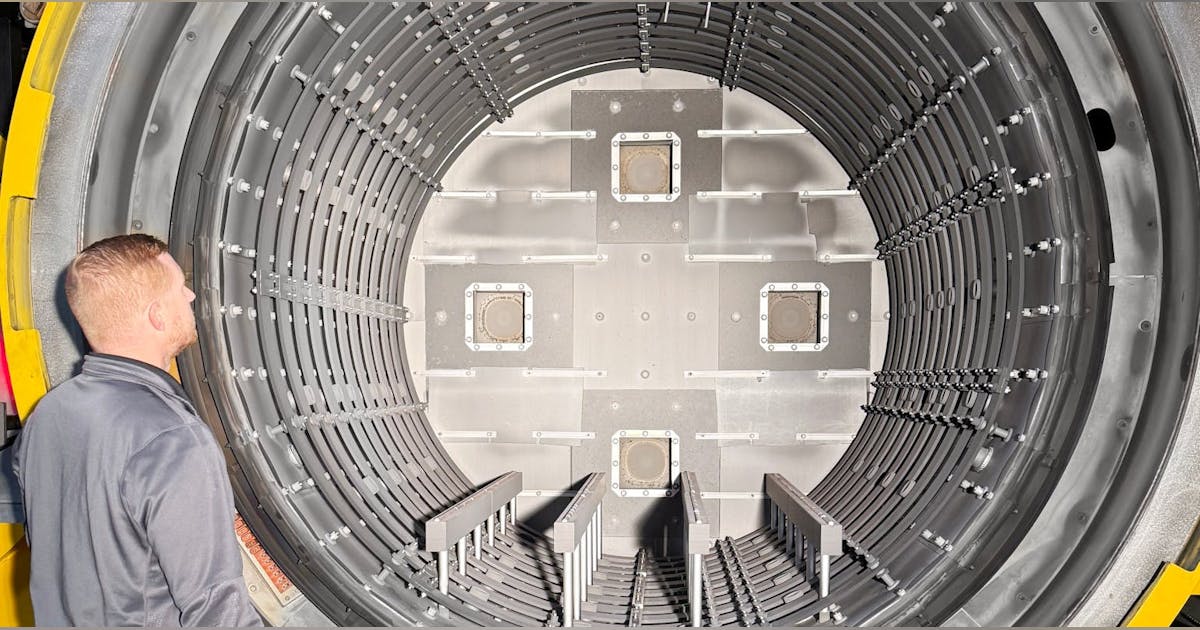

An Illinois industrial heat-treater has put in a model new, large-volume vacuum furnace to extend its fluctuate of capabilities for processing manufactured elements, significantly in automotive and aerospace sectors, in step with the furnace supplier. Photograph voltaic Manufacturing constructed and geared up the 48x48x72-inch deep furnace to FPM Heat Treating, noting that the chamber is completely compliant with NFPA, NADCAP, AMS, CQI-9, and totally different industrial necessities.

FPM Heat Treating operates two vegetation, in Elk Grove Village and Cherry Valley, IL, and affords a wide range of batch and regular remedy firms, metallurgical testing, and totally different firms.

“We’re devoted to meeting the rising requires of our consumers inside the manufacturing group,” stated FPM Heat Treating v.p. Bob Ferry. “The model new Photograph voltaic furnace enhances our capabilities and permits us to maintain up the perfect necessities of top of the range and effectivity in our operations.”

The model new furnace affords an working temperature of as a lot as 2400°F and a weight functionality of 5,000 kilos, so it is suited to conducting specialised heat-treatment cycles for automotive elements. Its programming flexibility makes it accessible for a wide range of thermal cycles, as may be needed by a industrial heat treating operation.

The unit may also be sufficiently versatile to maintain up the precise specs required for shopper, safety, and aerospace sectors, along with eliminating intergranular oxidation.

Photograph voltaic Manufacturing outlined that FPM’s number of FPM’s new furnace was a response to “an rising demand for a specialised family of elements.” It did not specify these elements, however it added that the demand is projected to rise steadily by the highest of the 2020s.