Extreme-volume manufacturing operations typically often should not the place to establish course of enhancements, nonetheless inside the case of diecasting an idea has emerged that can counter that notion. Ferrofacta GmbH is asking consideration to its effort to adapt a hot-runner strategy associated to plastic injection molding to manufacturing of zinc diecastings, which might be pretty usually produced in very extreme volumes.

Zinc is usually a commodity-grade supplies chosen to supply lightweight, heat- and wear-resistant components like clamps, fittings, flanges, however it certainly provides design value with regards to holding shut tolerances and dimensional stability for numerous sizes and styles. All these components, plus recyclability, make zinc attention-grabbing to designers of automotive and electronics components and housings, too.

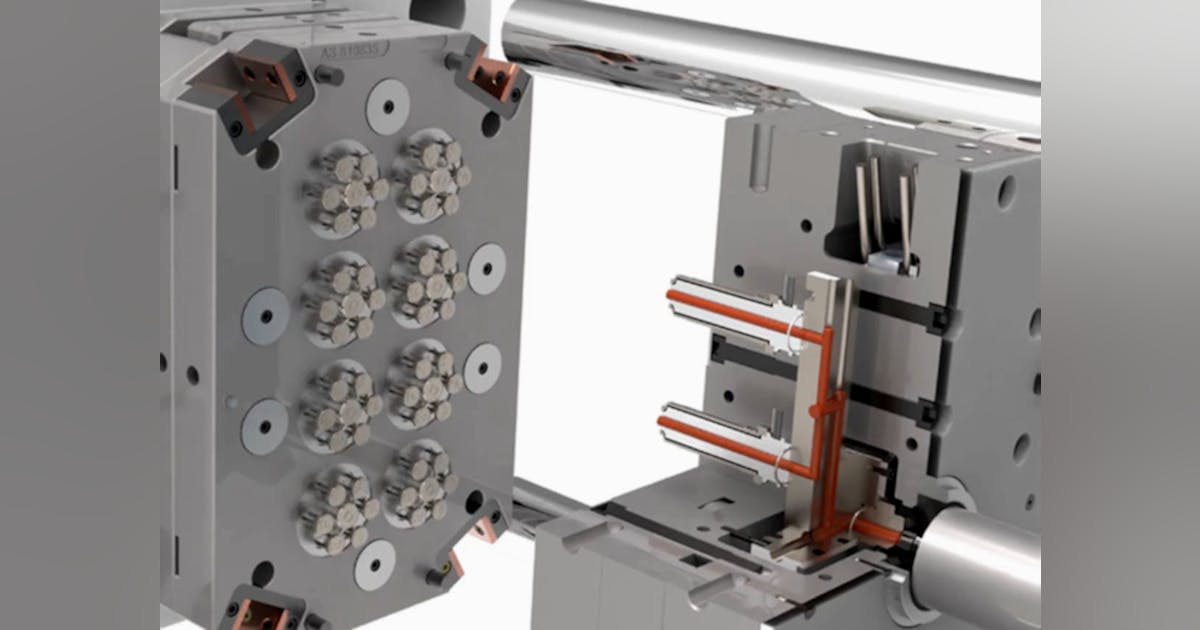

Conventionally, diecasting is completed using a hot-chamber system: molten metal is drawn proper right into a heated chamber or cylinder, after which pressured pneumatically or hydraulically by a sprue proper right into a die. For diecasting further difficult components, a sprue bushing may be used to direct molten metal by runners and gates into the die cavities.

The system that Ferrofacta has patented parallels the plastic injection molding course of, serving molten metal by the runner with out gating. It claims this “scorching runner” system makes it attainable to feed a single difficult die from quite a lot of injection elements, or to serve metal to quite a lot of dies. Reportedly this method reduces the amount of metal scrap and can enhance diecasting cycle cases versus further normal processes.

One different reported profit is more healthy top quality cast components – significantly, metal with a lot much less porosity because of there’s a lot much less air entrained inside the runner system, and better ground circumstances because of molten zinc temperatures, and that problem moreover contributes to elevated productiveness because of there are fewer accomplished components rejected for prime quality factors.

Extending the logic a step extra, injecting molten zinc into the mould establishes the potential for sophisticated, thin-wall designs, which together with top quality surfaces will promote manufacturing of higher-value diecastings. This aspect is supported by the availability of newer, high-strength zinc alloys acceptable for thinner, sturdier for housings or {{hardware}}, for example.

Among the many many potential, high-volume merchandise suggested for zinc diecastings are electrical housings or covers, or laptop computer laptop and phone cases, produced immediately from a diecasting machine.

In overview, Ferrofacta argues that its scorching runner system makes the diecasting course of additional adaptable to new manufacturing functions, with sooner set-ups and reduce tooling costs. The experience behind hot-runner diecasting is part of the system design, so machine programming is straightforward too. This simplicity could even cope with the skilled-worker shortage that so many metalcasting operations face.

Lastly, the developer moreover makes a case for the sustainability of its scorching runner system. Rising the throughput and productiveness of zinc diecasting reduces the extent of carbon emissions which will have resulted from recycling scrap metal.