TriTech Titanium is an funding caster and metal-injection molding operation that manufactures net-shape titanium components in small and large volumes, along with prototypes, for enterprise and industrial markets, along with aerospace, automotive, and marine prospects.

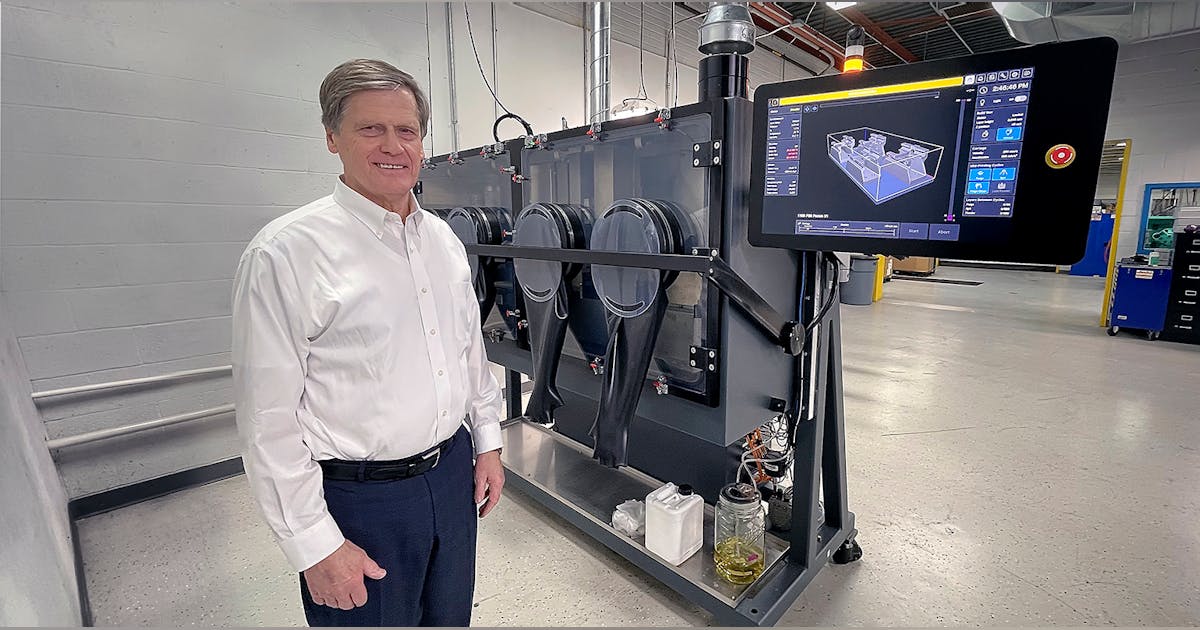

“With binder-jet 3D printing, titanium manufacturing of even primarily essentially the most superior geometries is perhaps enormously simplified and achieved at a lower value,” mentioned Robert Swenson, the proprietor of TriTech. “Our crew is extraordinarily proud to be the first Desktop Metal Manufacturing System P-1 purchaser worldwide to binder-jet 3D-print titanium, and we’re excited to provide this new manufacturing know-how to our prospects.”

Desktop Metal’s Manufacturing System sequence of binder-jet additive manufacturing strategies provide high-speed Single Go Jetting (SPJ) know-how on two fashions: the P-1, for evaluation and progress of binder jetting initiatives for serial manufacturing; and the P-50, which the developer calls “the world’s quickest metallic binder jet system, offering the underside value per half, with SPJ know-how.

Desktop Metal moreover currently launched {{that a}} chromium-zirconium copper alloy (C18150) has been licensed for manufacturing on its Manufacturing System sequence printers, and that 304L stainless steel has been licensed on its Retailer System mid-sized binder-jet printers.