The LIFT manufacturing evaluation institute reported a model new enchancment beneath its sponsorship involving a method for producing custom-made powdered metallic alloys. The evaluation by undergraduate teams at Michigan Know-how School reportedly will contribute to creating new provides and “freeway maps” for hypersonics functions.

LIFT is a public-private partnership of the U.S. Dept. of Safety and quite a lot of industrial and tutorial pursuits, working to stipulate manufacturing processes for lightweight provides. Michigan Tech may also be working with LIFT throughout the ongoing Hypersonics Thermal Administration and Supplies Acceleration packages, funded by DoD, to stipulate roadmaps for creating alloys and processes for industrial, off-the-shelf provides which can be produced by additive manufacturing for hypersonics.

Hypersonic weapon strategies perform at speeds of Mach 5 or elevated nonetheless in low-Earth atmospheres. Creating such weapons, along with a house present chain for them, are amongst DoD’s prime priorities.

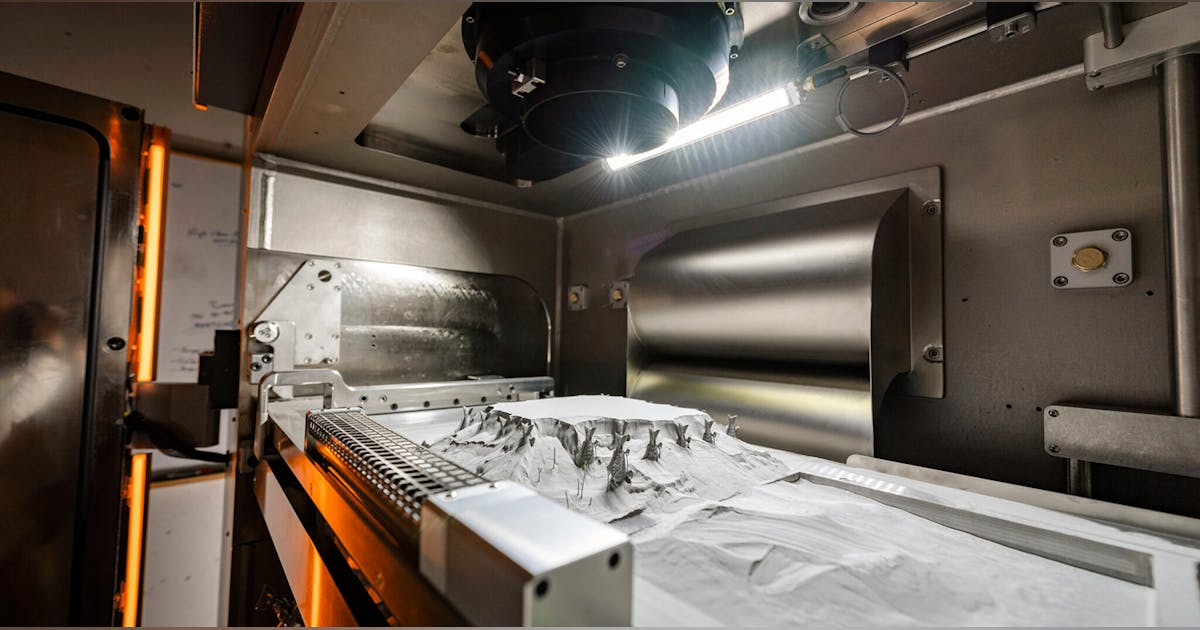

The model new powder-metal manufacturing course of was developed by 4 teams of Michigan Tech faculty college students and features a 10-ft-tall modular chamber into which molten metallic is poured by the use of a funnel, after which atomized using a high-pressure gasoline nozzle. The powdered metallic thereby created is collected from the underside of the chamber.

The chamber is designed to atomize about 88 lbs. (40 kg) of metallic, along with ferrous metals, nickel-based alloys, and aluminum-based alloys.

Atomization is a traditional manufacturing course of for PM nonetheless the manufacturing functionality is restricted for the types of alloys needed for superior evaluation packages, and Paul Sanders, a Michigan Tech professor of Provides Science and Engineering who served as college advisor to the 4 teams, said the teams’ work will promote enchancment of current alloy metallic powders.

“This atomization performance is required on account of current powders for metallic additive-development duties are expensive and have prolonged lead-times,” primarily based on Sanders. “This chamber, if constructed and deployed, will current for improved powder additive alloy design sooner and at a lot much less worth all through enterprise.”

LIFT’s chief experience officer Noel Mack said presently obtainable parts for custom-made PM alloys are each too small or too big for environment friendly evaluation. “The potential of making purchaser powders specifically portions may tempo up our innovation processes of future functions, corresponding to provides for hypersonics, and as a result of this reality tempo up the adoption by enterprise,” Mack said.

Michigan Tech may also be partnered with LIFT throughout the ongoing Hypersonics Thermal Administration and Supplies Acceleration packages, every funded by the use of the Dept. of Safety, to develop roadmaps for alloy and course of enchancment for off-the-shelf provides for additively manufactured parts, for use in hypersonic functions.